TPG -The Parkside Group’s BES 6001 Responsible Sourcing Initiatives

Material Recycling

Aluminium Re-Cycling – A Sustainable Solution

With Sustainability issues at the top of the global ‘green’ agenda, the building industry is now more than ever under close scrutiny. The aluminium industry is making a positive and proven contribution and global recycling rates are high, up to 90% for construction and transport applications against 60% for beverage cans. The fact that 100% of aluminium can be recycled at the end of its design life creates an aluminium bank for re-use in the future and 5% of the original energy required from primary extraction is required at re-smelting. Aluminium can be recycled over and over without loss of properties, ensures that the high value of aluminium scrap remains a strong incentive and financial impetus for recycling. This can only benefit future generations by conserving energy and saving up to 95% of the energy required for primary production, therefore avoiding corresponding emissions, which include greenhouse gases.

Therefore, as well established valuable cradle-to-cradle material, aluminium really does offer the solution to today’s serious sustainability concerns. The main uses of aluminium are evident in the construction of windows, doors, curtain walling and facades. These can be seen across many types of building from a local high street glazed shopfront to the superstructure of a stadium or flagship shopping development.

Architects have been aware of Aluminium’s unique qualities for over a century. Aluminium being one of the most globally abundant materials available, its formability, high strength-to-weight ratio, corrosion resistance and ease of recycling make it the ideal material for a variety of building applications. Commercial windows and doors must meet a myriad of functions and be environmentally sustainable, be weather resistant, secure and be energy efficient.

Sustainable Approach – Certificated to BES 6001 3.01

At TPG -The Parkside Group Limited we recognise the importance of our Purchasing decisions and the impact they may have on our environment and society. We encourage our Supply Chain to implement a certified Quality, Environmental, and Health and Safety Management System. We also recognise the importance of Environmental Protection and we are committed to operating our business in compliance with all Environmental Regulations, Legislation and initiatives relating to the building industry and the wider Environment.

It is the organisation’s objective to operate with, and to maintain good relations with all regulatory bodies and places Environmental Protection at the core of it’s operations. The Parkside Group Limited is accredited to the Environmental Standard ISO 14001:2015 and BES 6001 3.1

The Parkside Group is committed to conducting its business in an open and honest manner and as such this our Corporate Social Responsibility (CSR) policy reflects the commitment of our employees to minimise the impact of our operations for future generations and ensuring the welfare of its staff and the local area. We pride ourselves with promoting all we do in an ethical and integral way.

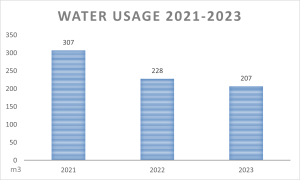

As part of our commitment to responsibly sourcing we continuously monitor the impact of our working practices and the design of our systems to ensure any environmental impact is minimised. For instance we used to hold a Water Abstraction License for the cleaning of our Lorries, but recognised the impact and now utilise alternative methods which do not drain this precious resource.

There are a number of ways in which we continue to reduce our impact on the environment:

- Continual Supplier Assessment

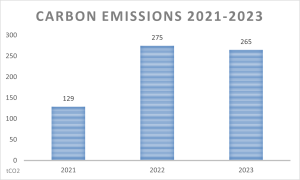

- Continual assessment of our carbon footprint shows a year on year reduction

- Water Usage is down 74.38% since 2013

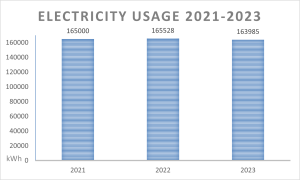

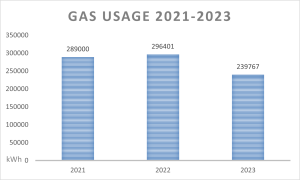

- Since 2012 our Electricity usage is down by 57.54 and our Gas usage is down by 28.27%

- New product development ensures we now include products which are both Passivhaus Certified and Kitemarked.

- Working in partnership with the Council for Aluminium in Building (CAB) on recycling cradle to cradle schemes.

Corporate Social Responsibility

The Parkside Group is committed to conducting its business in an open and honest manner and as such this policy reflects the commitment of our employees to our CSR policy, to minimise the impact of its operations for future generations and ensuring the welfare of its staff and the local area. We pride ourselves with promoting all we do in an ethical and integral way.

This Policy highlights our obligations, to all connected with our group and below is listed standards of conduct all employees must abide by as well as duties to report any suspected breaches of this policy by others. If any suspected breaches are reported the “reportee” should be assured that any concerns will be handled confidently and will not suffer any detriment treatment for reporting the said concern.

Responsibility for monitoring and reviewing these measures is the task of the audit committee who consist of staff, managers and directors from all departments across the Organisation. Listed below are our policy statements to encourage all to be accountable for the social, environmental and economic impact of our operations.

- The Organisation is committed to providing a welcoming, service led organisation for our staff and our business partners, that develops talent, supports the families of all our staff and our client base. We expect our staff to behave in an ethical way throughout their business dealings.

- As an Organisation we donate to both local community groups, charities and draw our workforce from the diverse mix that is the UK and actively encourage employment from locally deprived areas.

- The Organisation regularly donates to charities by way of department events and we encourage our staff to support their local communities individually by way of charity events and voluntary support. We also support our business partners with their own charity events.

- Environmentally the Organisation works to minimise the impact of our operations for future generations, this is the cornerstone of our environmental management system, which actively year on year reduces our waste, use of materials, energy and water. Our EMS system is accredited to ISO14001:2015 and we hold BES6001. We expect our suppliers to accredit themselves to this standard.

- The Organisation ensures that our suppliers are paid within their terms to help build long term mutually beneficial supplier relationship. We expect our clients throughout the construction industry to offer payment terms which reflect our core values to ensure the survival and operation of our business partners.

- The Organisation encourages staff to actively communicate different approaches to promote and assist with our continued aim to our social, economic and environmental responsibility.

- We comply with all applicable laws, regulations and other employment standards and actively promote our other business policies to all our staff and business partners.

- As an Organisation we seek not to deal with suppliers or countries that have a poor record of human rights violations or permit the use of child labour, and we expect our business partners to comply with the Human Rights Act 1998. In today’s economic environment we feel having strong suppliers who reflect our own family and community values, ensures that The Parkside Group Limited contributes to the ethics of a good global citizen.

As part of TPG’s CSR policy we are delighted to support the following:

- Macmillian Nurses

- Border to Border for Hope House

- Sikh Welfare

- Cancer Research

- 2016 Great Birmingham ½ Marathon – Acorn’s Children’s Hospice

- Norwood (Supports disabled children) Charity bike ride

- Royal Marsden Hospital Fundraiser

- Freedom Flight Prize Sponsor

- Royal Marsden Cancer Charity

- Macmillan Cancer Support

TPG: 2025 – For Future Generations

The processes that are critical to success within the organisation are aligned to aid our clients to achieve the Governments “Construction 2025” objectives: to create sustainable value for our supply chain partners.

People

Human resource management is our number one priority, in terms of the retention, training well-being, health and safety of all our staff and our partners. We continually improve through independent audits of our BSi’s ISO 45001:2018 Health & Safety Certification.

Innovation

We launched our Innovation Strategy for New Product development in 2009 to ensure our partners have products and BIM technologies which both exploit market opportunities and perform to exceed the very latest standards.

Sustainable Value

We create sustainable value by minimising our impact on the environment by managing our supply chain through responsibly sourcing, which is audited and certified through BSI’s BES 6001 3.1 and maximising growth through the strategic management market opportunities.

Delivery Excellence

Maintain our market leading delivery in terms of profiles, customer service and economic efficiencies.

Leadership

Board level commitment to champion new technologies and business processes to the organisation, coaching and committing to best practice throughout the hierarchy.

Responsible Sourcing

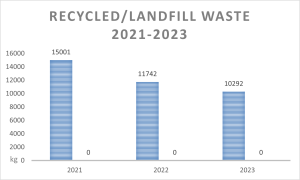

Recycled/Landfill

Since 2022 we have reduced our overall waste by 13%.

Utilities

Since setting our Base Line in 2013 we have exceeded our goals year on year in reducing our usage of gas/electricity/water.

Communication to the Organisation

Regular engagement with the organisation to actively promote and communicate our strategy for waste prevention and recyclability.

These objectives and their outputs are detailed in the section below “Minimising Our Impact”

Minimising Our Impact

At TPG we strive to minimise our carbon footprint, and set ourselves tough targets to reduce our impact on the environment.

We monitor our environmental impacts and the following charts summarise how we are continuously improving year on year.

We also try to counteract the carbon dioxide emissions that are still resulting from operations despite the annual improvements we do achieve, by supporting carbon offset initiatives.

This year we have offsetted 265 tonnes of carbon dioxide emissions by supporting the Wind Power Project In Tamil Nadu.

Sustainability Statement

Today’s world calls for us all to be more conscious of our environment. In 1998 the world recognised this by signing the Kyoto Agreement. The Kyoto Agreement directly affected the construction industry by demanding that buildings become more thermally efficient. With these demands longevity, thermal efficiency, sustainability and recyclability are now critical factors in construction.

Aluminium provides a unique solution for today’s construction needs. Aluminium is light, strong, durable and flexible which provides tremendous potential for achieving even the most demanding design brief. Two-thirds of the energy required to extract aluminium is supplied by environmentally friendly, hydroelectric power. Couple this with the cradle-to-cradle recyclability of aluminium, presents aluminium as the ideal choice for facades and the construction industry

Unlike some alternative building materials, aluminium offers an almost unlimited life expectancy. A notable example of this is the Statue of Eros in London’s Piccadilly Circus, which has been cleaned and renovated, and the Empire State Building, the latter being the first building to use anodised aluminium. Aluminium does not age like other organic materials and needs no protection from ultra-violet light. Aluminium can be polyester powder coated or anodised to a variety of colours, which enhances the material’s natural durability. Comar’s preferred powder coater guarantee their finishes for 25 years and anodiser’s for 35 years. However, with proper maintenance aluminium has an indefinite life expectancy.

The recycling process now produces high quality aluminium, which is very cost effective and can be carried out on an indefinite number of occasions without impairing the quality in any way. It is a very durable material and has very low maintenance requirements, therefore reducing the whole life cost. It is long lasting and can withstand the ravages of the most extreme conditions. Aluminium is an excellent material to use in marine and coastal environments, as the effect of sodium chloride is minimal. Sustainability concerns are alleviated by the knowledge that we have at least 300 years of known reserves of the raw material, Bauxite, and this does not allow for the fact that 85% – 95% of all aluminium used is recycled at the end of its product life. Thus with an ever increasing proportion of re-cycled material in use, aluminium can be accurately described as the ultimate sustainable material.

“The recyclability of aluminium – one of its unique properties along with strength, durability and corrosion

resistance – has led to its increased use in construction over recent years. Used aluminium is valuable and

is easily and endlessly recycled without quality loss. The material is very rarely ‘lost’ entirely because of this.”

Important issues to note are:

- The quality of aluminium is not impaired by endlessly recycling

- Re-smelting aluminium saves up to 95% of the energy needed to produce the primary product

- It is the most cost effective material to recycle

- The overall market for used aluminium is steadily growing, the more aluminium in a product,

the more chance it has of being recycled - The recycling rate of used aluminium products in building is between 85-95%

(over 95% in transportation and 30% in packaging) - 3% of the 1.9 million tonnes of aluminium used in Europe in 1997 came from recycling

Supplier Assessment

Supply Chain Management

For many years now our organisation has been implementing and improving our Environmental and responsible sourcing activities. Taking responsibility for our environmental and social impacts begins at the design and development stage, this then extends to the promotion of sustainability throughout our supply chain.

The Parkside Group Limited view our suppliers as an integral part of business and strive for transparency and efficient collaboration within our supply chain partnerships, this ethos benefits our stakeholders and customers alike.

We pride ourselves in actively promoting all we do in an ethical and professional manner. Our Purchasing staff are trained in the important issues concerning modern slavery and how to prevent and eradicate it through their work.

Assessment Process

Our Supply Chain Management Strategy is the continued management and development of our preferred supplier list. We insist that all new and established supply partners periodically complete our comprehensive supply chain appraisal questionnaire. This information, as well as their supply and quality performance, their current legal compliance (plus any other areas which are subject to assessment) provides us internally with a valuable and measurable scoring mechanism, with only the best suppliers retained on our preferred supplier list.

Where a supply partner falls below our expectations we would insist that they review their procedures and processes to ensure improvement. We work closely with our suppliers to identify poor performance areas and assist in the development of strategies for improvement.

If significant non-conformances are identified, for which there is no resolution a supplier can be removed from our preferred supplier list.

Regular meetings take place with our supply partners where areas of concern can be discussed and agreed, along with any required new process that may need to be put into place to ensure continual improvement. We encourage all supply partners to conform to ISO9001, ISO14001 and ISO45001.

Links

Certification

Click the links below to view or download the Parkside Group Certificates: